Smart Fruit grading machine

An AI and IoT-enabled fruit grading machine is a cutting-edge solution for the agricultural industry, designed to automate and optimize the process of sorting fruits based on various quality parameters. This technology significantly improves efficiency, reduces labor costs, and ensures consistent quality in the produce market.

For Sale

Smart Fruit Grading Machine

Get in touch

+91 8840055945

. How it Works (Core Functionality):

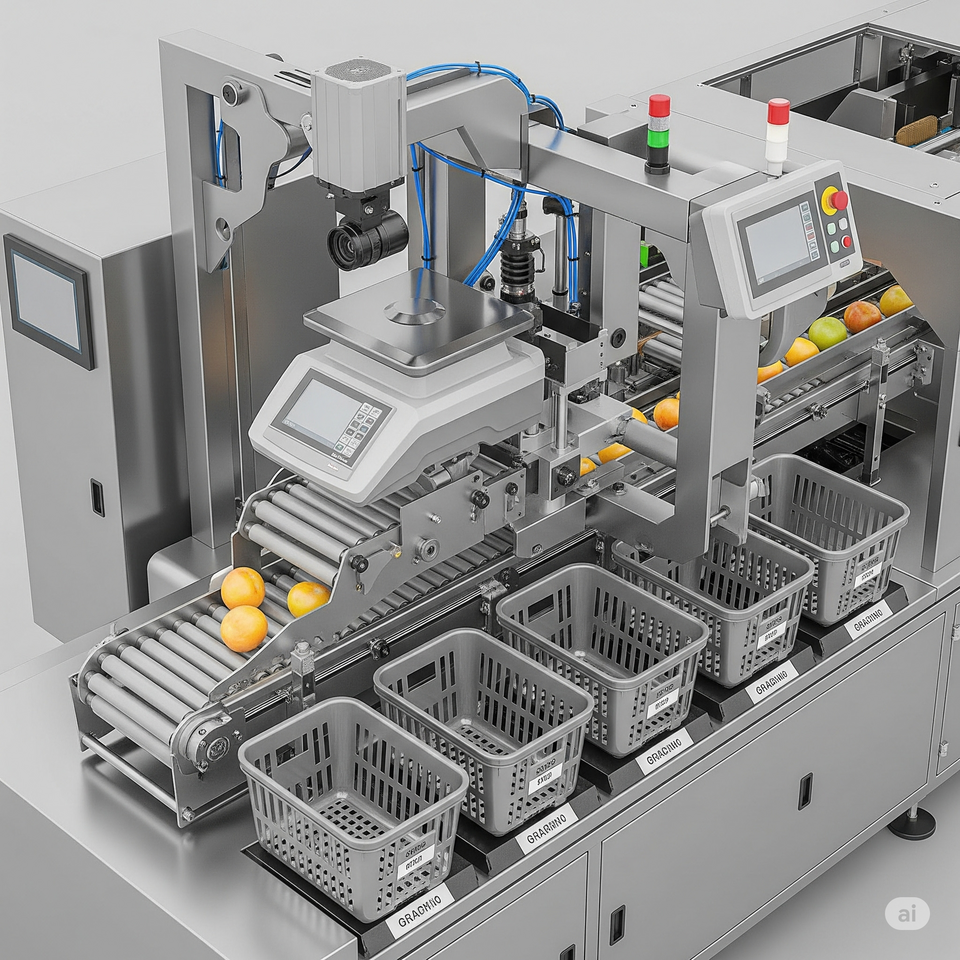

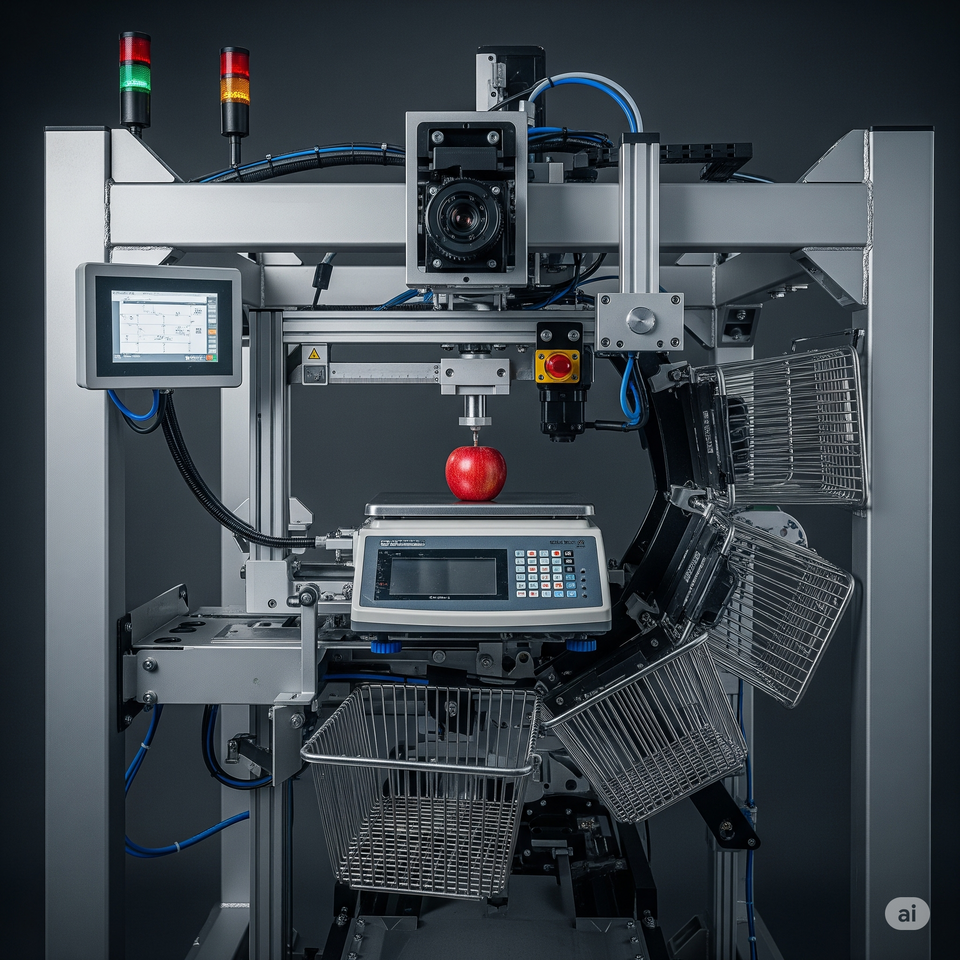

Fruit Feeding: Fruits are typically fed onto a conveyor belt system.

Data Capture (IoT & Sensors): As fruits move along the conveyor, they pass through a sensing station equipped with:

High-resolution cameras: These capture multiple images of each fruit from various angles to assess external characteristics.

Weight sensors (load cells): Precisely measure the weight of each fruit.

Other sensors (optional): Depending on the desired grading criteria, these could include:

Spectrometers (for internal quality like sugar content, ripeness, or internal defects)

Proximity sensors (for accurate positioning)

Data Processing and Analysis (AI/Machine Learning):

Image Processing: AI algorithms (often Convolutional Neural Networks - CNNs) analyze the captured images to extract features related to:

Color: Identifying ripeness levels, blemishes, or discoloration.

Shape: Detecting irregular shapes, deformities, or bruises.

Size: Measuring dimensions (length, width, diameter) for categorization.

Data Fusion: The data from all sensors (color, shape, size, weight) is combined and fed into the AI model.

Classification & Grading: The trained AI model classifies each fruit into predefined grades (e.g., A, B, C, or specific categories like "ripe," "unripe," "damaged"). This classification is based on complex patterns learned from a large dataset of previously graded fruits.

Sorting/Actuation: Based on the AI's classification, an automated actuation system (e.g., robotic arms, pneumatic pushers, or tilting mechanisms) directs each fruit to its designated collection bin or conveyor line.

Data Recording (Server & IoT): All the collected data (fruit ID, grade, measured parameters, time of sorting) is recorded and stored in a central server. This server can be local or cloud-based, enabling:

Real-time monitoring: Operators can view sorting progress and performance remotely.

Data analytics: Historical data can be analyzed to identify trends, optimize processes, and provide insights into crop quality and yield.

Traceability: Provides a record of each fruit's journey from sorting to packaging.

2. Key Features and Technologies:

Computer Vision: The backbone of the system, enabling the "seeing" and analysis of fruits.

Deep Learning/Machine Learning: Especially CNNs, for accurate and robust classification of fruits based on visual and other sensor data.

Internet of Things (IoT): Connects sensors, actuators, and the central server for real-time data exchange, remote monitoring, and control.

Robotics/Automation: Mechanical components like conveyor belts and sorting mechanisms for efficient handling.

Cloud Computing (Optional): For scalable data storage, processing, and remote access to dashboards and analytics.

3. Benefits:

Increased Efficiency and Speed: Automates a highly labor-intensive process, sorting fruits much faster than manual methods.

Higher Accuracy and Consistency: AI eliminates human error and subjective judgment, ensuring uniform grading standards.

Reduced Labor Costs: Minimizes the need for manual sorting, leading to significant cost savings.

Improved Quality Control: Detects even subtle defects, leading to higher quality produce reaching the market.

Reduced Food Waste: By accurately identifying and segregating damaged or lower-grade fruits, it minimizes spoilage and maximizes the usable yield.

Data-Driven Insights: Provides valuable data on crop quality, yield, and sorting performance, enabling better decision-making for farmers and distributors.

Enhanced Traceability: Records data for each fruit, improving supply chain transparency and food safety.

Customization: Can be programmed to meet specific grading criteria and standards required by different markets or customers.

24/7 Operation: Unlike human labor, the machine can operate continuously, boosting productivity.

4. Components:

Conveyor System: To transport fruits through the machine.

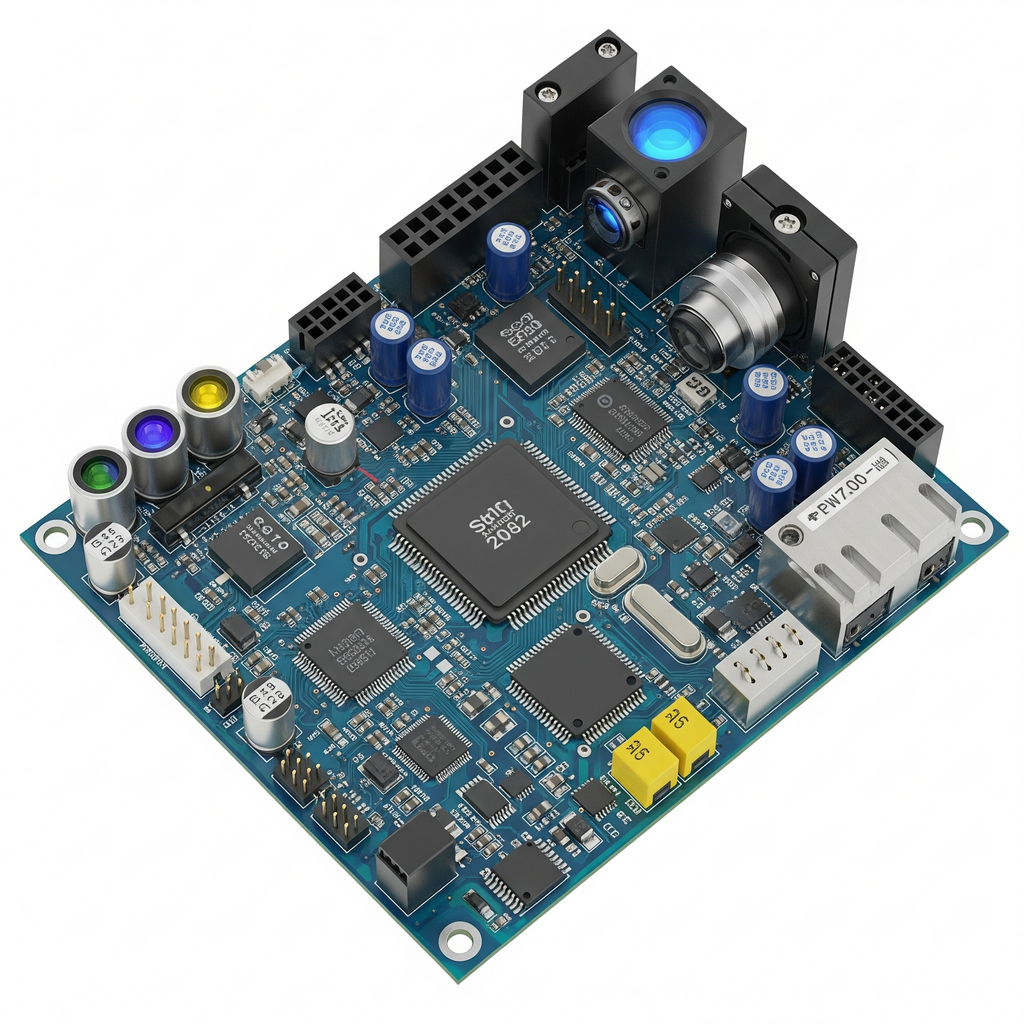

Imaging System: High-resolution cameras, lighting (often diffused LED lighting for consistent imaging).

Sensors: Weight sensors (load cells), potentially NIR (Near-Infrared) or hyperspectral sensors for internal quality.

Processing Unit: Embedded computers (e.g., Raspberry Pi, industrial PCs) with GPUs for AI model inference.

Actuation System: Solenoid valves, pneumatic cylinders, servo motors, or robotic arms for sorting.

Software:

Image acquisition and pre-processing software.

AI/ML model: Trained on a large dataset of fruit images and data.

Control software: To manage the conveyor, sensors, and actuators.

Data management software: For storing, organizing, and analyzing data.

User Interface (UI): For configuration, monitoring, and reporting.

Networking/Communication Modules: For IoT connectivity (Wi-Fi, Ethernet, cellular).

Server/Cloud Platform: For data storage, analytics, and remote access.

5. Cost:

The cost of an AI and IoT-enabled fruit grading machine can vary significantly depending on its capacity, complexity, features, and the manufacturer.

Basic Semi-Automatic Machines: Can start from around INR 1.35 Lakhs to INR 3-4 Lakhs.

Fully Automatic, High-Capacity Machines with advanced AI and IoT features: These can range from INR 5 Lakhs to well over INR 90 Lakhs, or even more for large-scale industrial solutions.

Factors influencing cost include:

Throughput (tons per hour): Higher capacity machines are more expensive.

Number of grading categories/lanes.

Types of sensors used: Machines with advanced internal quality analysis capabilities will cost more.

Level of automation: Semi-automatic vs. fully automatic.

Brand and manufacturing quality.

Customization requirements.

Overall, these machines represent a significant investment but offer a strong return on investment through increased efficiency, reduced waste, and improved product quality, which translates to higher market value for farmers and processors.